What if structural reinforcement didn’t require molds, layups, or compromises?

In Spain, one advanced manufacturer is already proving it’s possible.

Reinforce3D and Pantur marked a key milestone in the journey to bring structural reinforcement into real production workflows — presenting the Continuous Fiber Injection Process (CFIP) live for the first time on a Service Bureau in Spain, and launching a new reference point for functional additive manufacturing.

“This partnership is a major step for Reinforce3D. Pantur’s experience and vision make them the ideal ally to bring CFIP into real production.” — Blanca Garro, CEO, Reinforce3D

Pantur is the first service bureau in Spain to integrate CFIP into its production environment. With over 30 years of experience in prototyping, tooling and manufacturing for demanding sectors such as aerospace, electronics, and industrial automation, Pantur represents a natural partner for CFIP adoption.

Together, we’re showing that advanced reinforcement is not a future concept — it’s a current, scalable solution for real parts and real production.

From printing to performance: reinforcement with CFIP

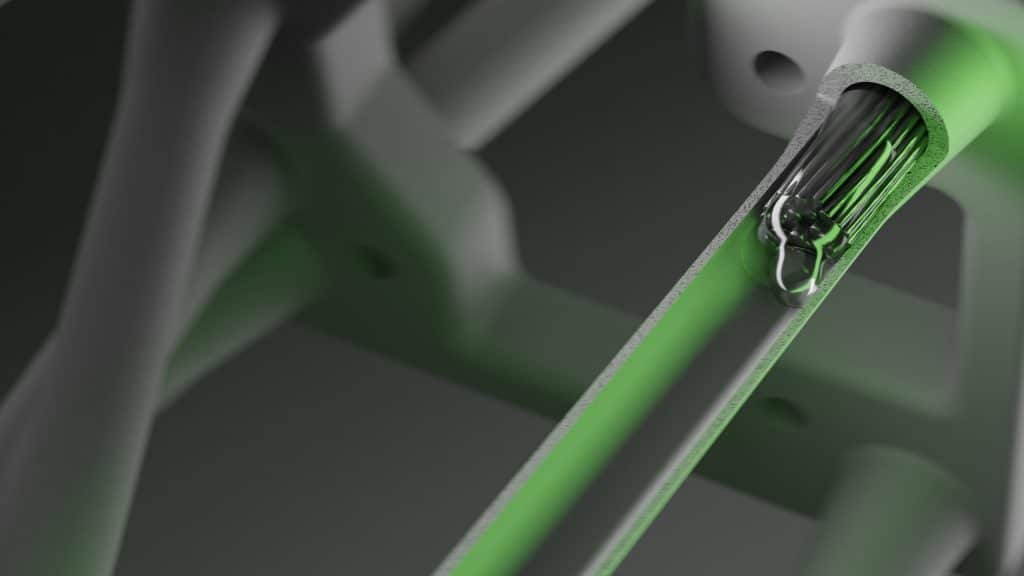

CFIP (Continuous Fiber Injection Process) is Reinforce3D’s patented solution that injects continuous fibers inside predefined cavities of printed or molded parts. The process aligns fibers with stress paths, creating structurally optimized components — without the need for adhesives, secondary assemblies, or composite layups.

The result? Lightweight, reinforced components with real mechanical performance — all through a clean, moldless, and automated process.

“With CFIP, we reinforce our position as an innovation hub. This technology allows us to offer our clients mechanical solutions that were unthinkable without molds or layup.” — Carles Martínez Huete, CEO, Pantur

Scaling functional composites, together

This milestone isn’t just about showing a machine or a process. It’s about giving industrial teams access to composite-grade strength in parts that were previously limited by weight, complexity, or tooling constraints.

By adopting CFIP, Pantur now offers its customers a new way to go beyond prototyping and deliver truly functional, structural components — ready for end use, ready for scale. From tooling to drones and beyond, this collaboration sets a precedent for what’s next in digital reinforcement.

Together, Reinforce3D and Pantur are proving that structural performance, design freedom, and digital scalability are not trade-offs — they’re now part of the same workflow.

The future of reinforcement is lighter, smarter — and already in production. Interested in exploring CFIP for your own parts or processes? Let’s talk.