CFIP is not just another additive technique

It is a patented post-process that turns parts into true structural composites. By placing continuous fibers along load paths, CFIP bridges the performance gap between plastics and metals — without compromising design freedom or scalability.

The new standard

DELTA , engineered for industrial scale

High-density fiber injection capability.

Real-time monitoring sensors for process control

Supports fibers such as carbon, glass, aramid, natural fibers as well.

Designed to evolve in scalable configurations.

The DELTA SYSTEM brings CFIP

into production

Built for precision, repeatability, and control, DELTA enables engineers to reinforce additive or molded parts with high-density continuous fibers. Designed to evolve with scalable configurations, it ensures industrial reliability today and tomorrow.

A smarter way to

reinforce parts

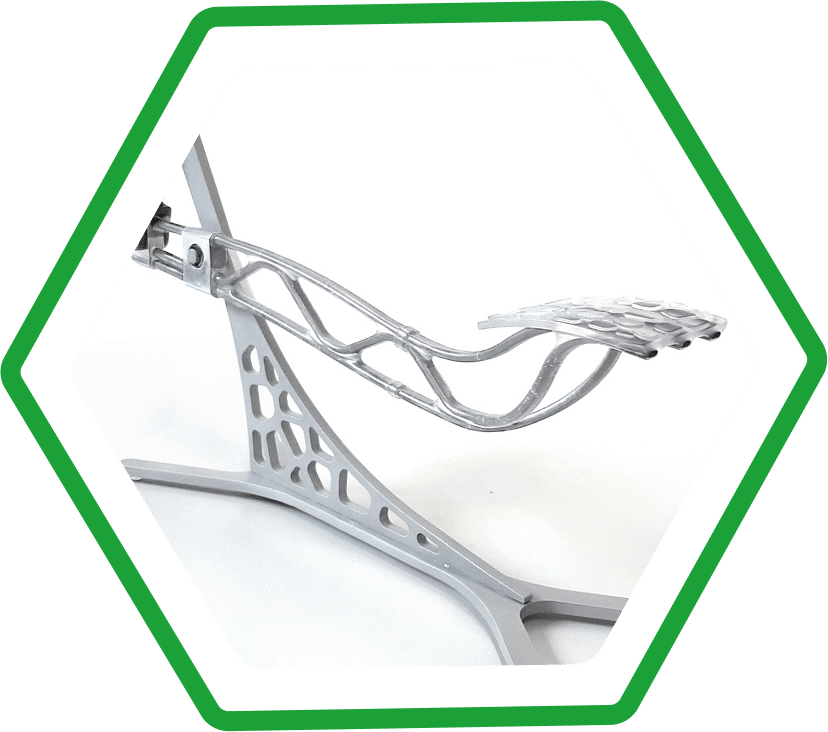

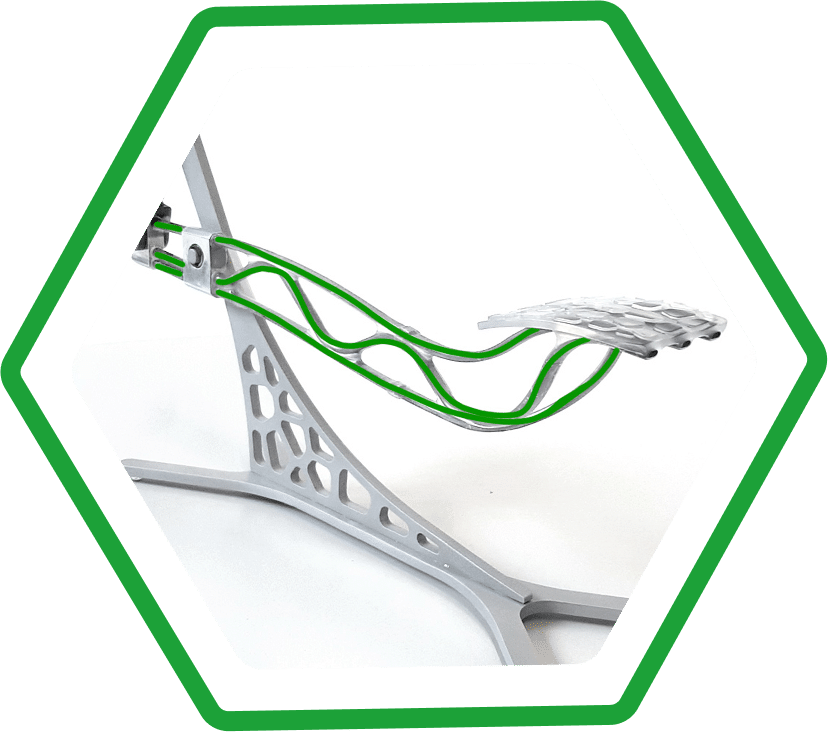

CFIP Technology is a post-process reinforcement technique that inserts continuous fibers directly into the internal tubular cavities of manufactured parts — adding structural integrity exactly where it’s needed most.

Unlike surface treatments or simple infill patterns, CFIP delivers true internal carbon fiber reinforcement while maintaining the part’s design freedom and weight advantage. Compatible with a range of engineering thermoplastics and hollow geometries, CFIP bridges the gap between polymer and metal performance.

Stronger, bigger, lighter… and most times, cheaper!

Performance without limits

Discover the benefits of CFIP

VERTICALS

Carbon-reinforced solutions for real-world industries

From aerospace to automotive, from sports equipment to industrial tooling — CFIP enables engineers to design parts that replace or outperform traditional composites and metals. The result: scalable reinforcement with unmatched performance and cost-efficiency.

Automotive

Customized

structural

reinforcement

AEROSPACE

Weight-critical

certified

components

SPORTS

Maximum

performance at

minimum weight

Industrial

Manufacturing

Maximum

performance at

minimum weight

Medical

Lightweight,

high-strength devices

CASE STUDIES / TESTIMONIALS

Built with purpose. Validated by industry.

DRONE VTOL REINFORCED WITH CFIP TECHNOLOGY

This whitepaper presents the development of a high-performance vertical take-off and landing (VTOL) drone using

REDUCING WEIGHT AND COST OF SATELLITE STRUCTURES WITH CFIP

Weight reduction is a crucial factor in thespace industry; the lighter a satellite is, theless

DRONE VTOL REINFORCED WITH CFIP TECHNOLOGY

This whitepaper presents the development of a high-performance vertical take-off and landing (VTOL) drone using