Business Case – Satellite Structures with CFIP

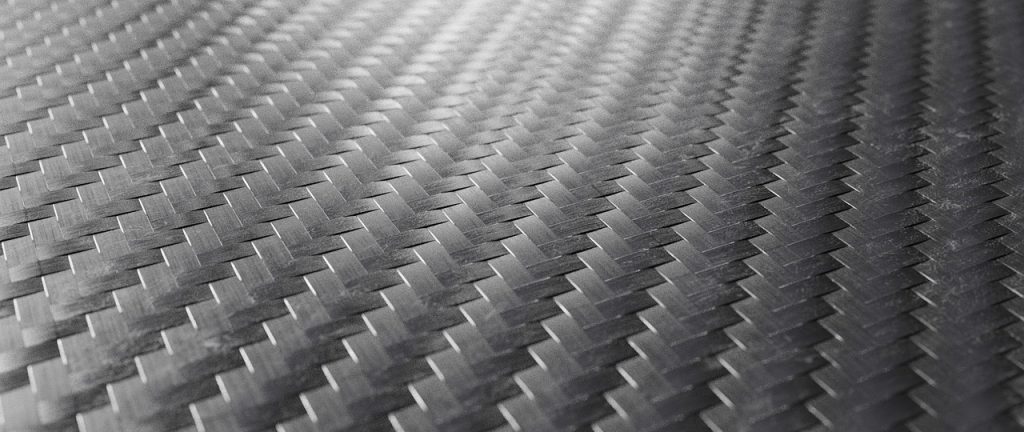

As well as being as light as possible, satellite components must also be stiff enough to perform under extremely harsh conditions in space and during the launch procedure. Aerospace manufacturers are therefore looking to utilise new design techniques and manufacturing methods, such as additivemanufacturing, in order to save as much weight and material as possible when producing their components.

Business Case – Satellite Structures with CFIP Leer más »