18th–21st November · Messe Frankfurt

Hall 12.0 · Stand C121

Two years after our first appearance at Formnext, Reinforce3D returns in 2025 with more momentum, more industrial validation,and a stronger-than-ever commitment to transforming how structural reinforcement is applied in additive manufacturing.

Since our debut, we’ve grown alongside the industry, bringing CFIP into real production environments, expanding our ecosystem, and collaborating with companies across mobility, aerospace, tooling, UAVs and performance applications. This year, we return not only to share what we’ve learned, but to introduce a new generation of reinforcement solutions that push the boundaries of where, and how, fiber injection can be implemented.

Our team will be there from the 18th to the 21st of November on Hall12, stand C121 to discuss how CFIP is helping companies across multiple sectors make their parts stronger, lighter and more scalable — without adding complexity to the production process.

Designing for strength, without constraints

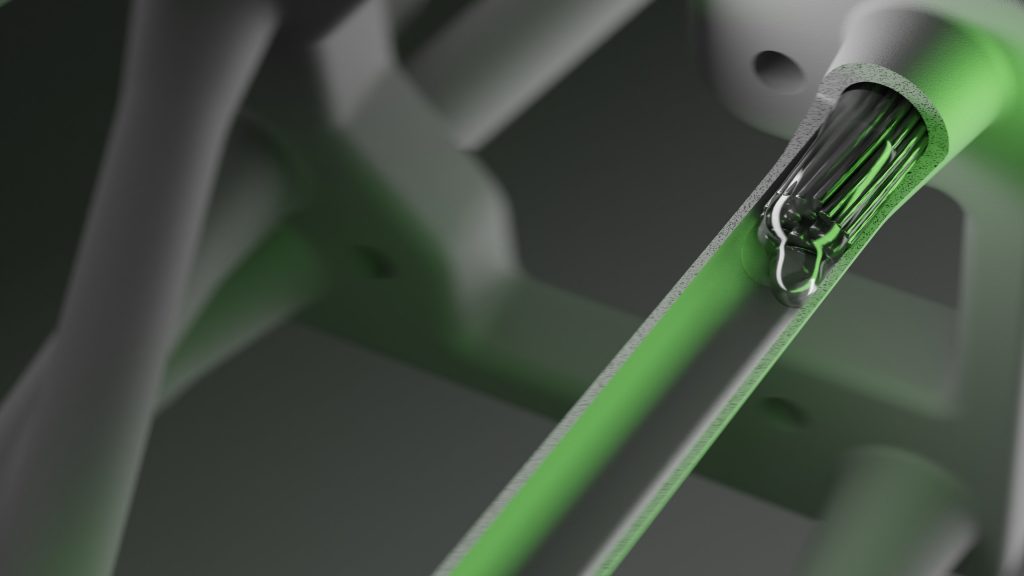

Unlike traditional reinforcements, CFIP (Continuous Fiber Injection Process) doesn’t require external laminates, inserts or bonding. There are no molds, no adhesives, and no need to redesign around foreign elements. The result is a fully integrated reinforcement, structurally effective from the inside, and fully compatible with additive manufacturing or hybrid workflows.

This approach allows to maintain full freedom of form while still meeting demanding mechanical requirements. Structural performance becomes part of the design logic — not an afterthought or compromise.

One of the main limitations of additive manufacturing in industrial contexts is the difficulty of moving from visual or geometric prototypes to functional, load-bearing parts. Many printed components look right but need to be overbuilt or post-processed to survive real use. That adds weight, time and cost — and often breaks the promise of design freedom.

CFIP helps bridge this gap. By reinforcing only where it’s needed, and doing so internally, the process enables printed or molded parts to reach levels of stiffness, strength and durability that are often only possible through traditional composite manufacturing — but without the overhead of tooling, layup or manual labor.

This opens the door to production-ready components that are lighter, simpler and more efficient, particularly in sectors like mobility, aerospace, drones, tooling and performance equipment, where performance-to-weight ratio is critical.

An ecosystem designed for scalability

To make all of this accessible, we’ve developed a full system 360º around CFIP. At the center is the Delta unit, our injection hardware designed to interface with additive or hybrid parts and apply fiber reinforcement at industrial level. Supporting it is our Design Checker software, a tool created in-house to evaluate parts before injection, analyzing cavity geometry, simulating fiber routing and validating structural feasibility.

Alongside hardware and software, we provide tailored material options, including carbon and glass fiber formulations, as well as engineering support for each phase of development. The goal is to make reinforcement easy to adopt, easy to validate, and easy to scale, even in demanding production environments.

Meet us in Frankfurt

At Formnext 2025, we’ll be available throughout the week to present our latest work, discuss use cases, and speak with manufacturers, engineers and innovation teams looking to strengthen their parts from within — structurally and strategically.

Whether you’re working with prototypes, pre-series or production runs, or simply exploring new ways to improve the mechanical performance of your parts, we’ll be glad to connect. If you’d like to schedule a meeting in advance, info@reinforce3d.com. We look forward to seeing you in Frankfurt, and to continuing the conversation on how to reinforce smarter.